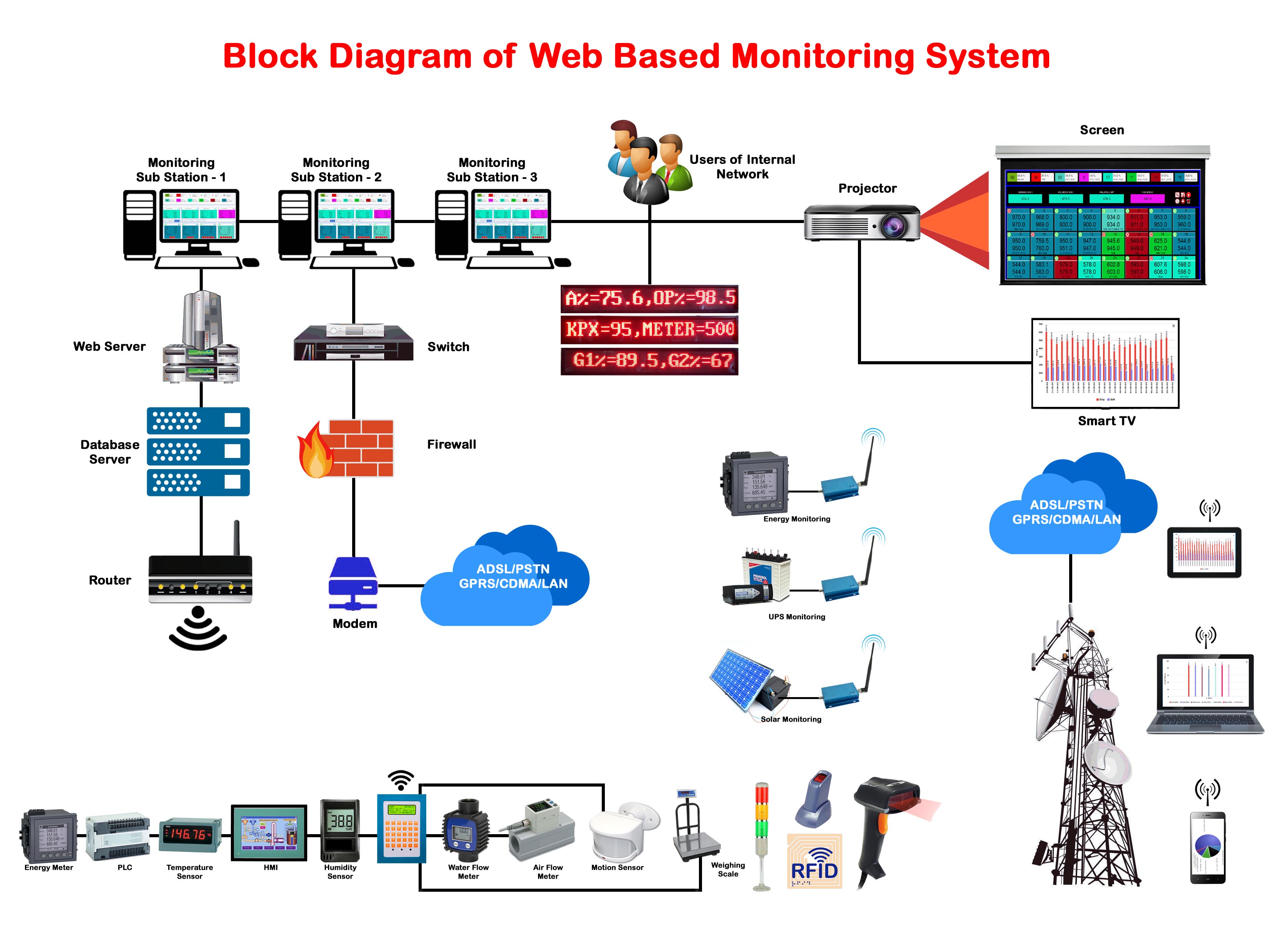

Web Based Monitoring System is the measuring and recording of physical or electrical parameters over a period of time. Some applications require only a single measurement, while others may require multiple channels and multiple types of measurements. Web Based Monitoring System is available with various channel configurations: single-channel devices, multichannel devices, and modular devices with a mixture of measurement types. It can measure different types of signals and sensors including the following Production (Kilo picks, CMPX), Stoppage (Warp, Weft, Others), Automatic & Manual Roll Doff, Line Voltage, Phase Voltage, Current, Kilo Watts, Frequency, Power Factor, KWH, Air Flow with Consumption, Water Flow with Consumption, Humidity and Temperature

This presents the following advantages over traditional stand-alone Web Based Monitoring System

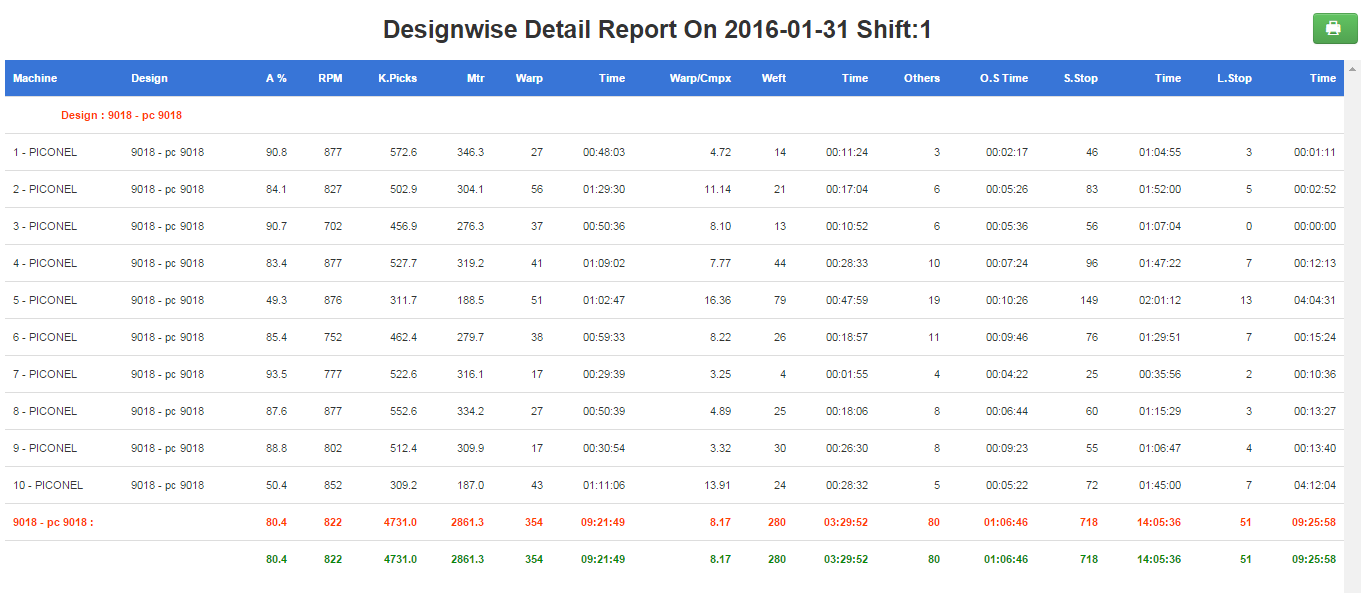

| Production Details | |

|---|---|

| Integrated All information about Machines at one Server | |

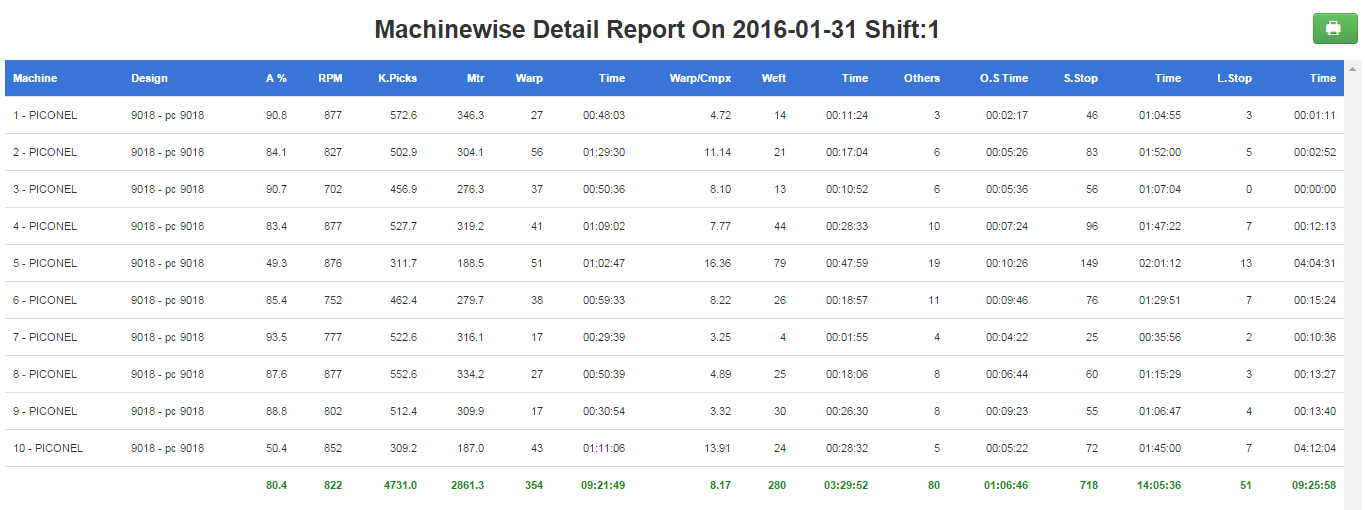

| Clarify Weak Areas | Machine Running Time |

| Actual Efficiency | Production Efficiency |

| Installed Efficiency | Utilization Efficiency |

| Instantaneous RPM and Average RPM | Production in Kilo Picks and CMPX |

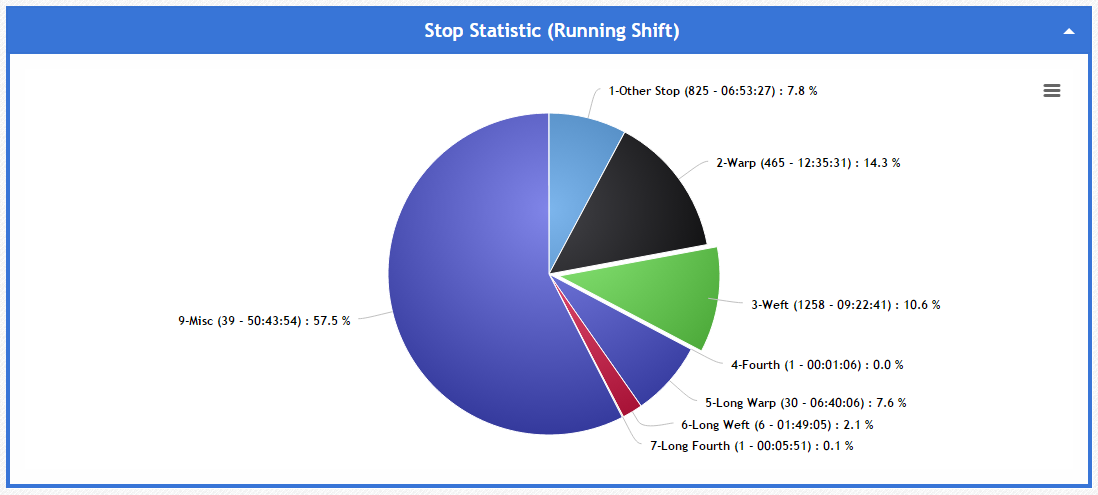

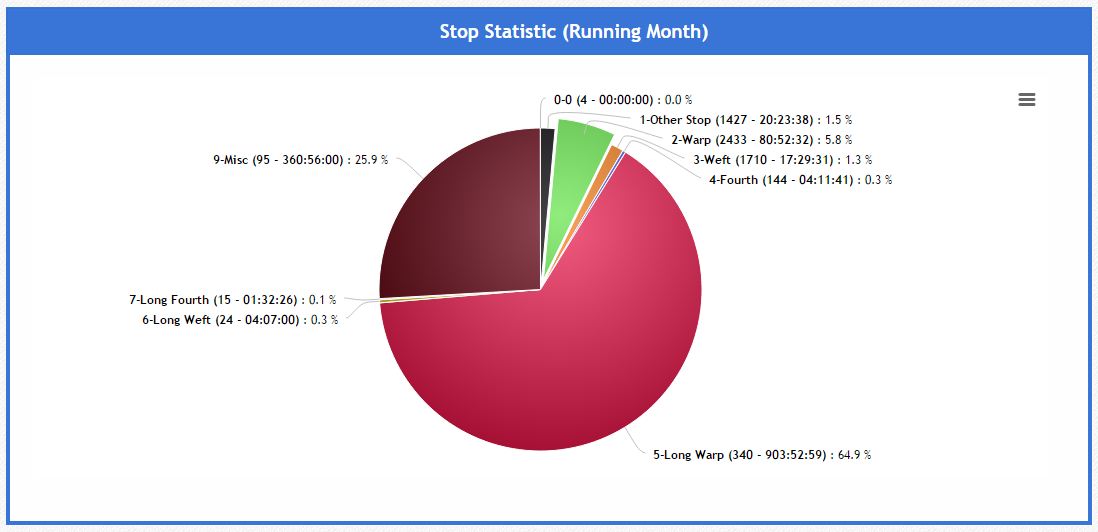

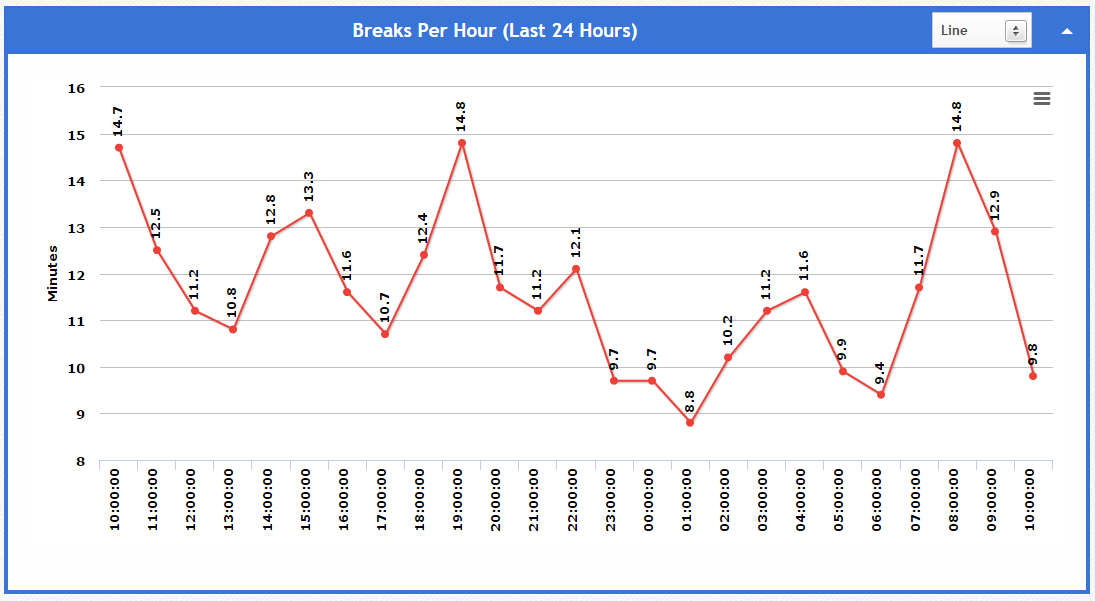

| Various Stop Time | Warp Stop with Duration |

| Minutes / Warp | Warp / Hour |

| Weft Stop with Duration | Minutes / Weft |

| Weft / Hour | Other Stop with Duration |

| Minutes / Other | Other / Hour |

| Short Stops with Duration | Minutes / Short Stops |

| Short Stops / Hour | |

| Run Suppress Pick Concept | |

| Pick / Runningtime Based Start Attempt | |

| Start Attempt For Warp Stop with Duration | Minutes / Start Attempt For Warp |

| Start Attempt For Warp / Hour | Start Attempt For Weft Stop with Duration |

| Minutes / Start Attempt For Weft | Start Attempt For Weft / Hour |

| Start Attempt For Others Stop with Duration | Minutes / Start Attempt For Others |

| Start Attempt For Others / Hour | Start Attempt For Short Stops with Duration |

| Minutes / Start Attempt For Short Stops | Start Attempt For Short Stops / Hour |

| Long Stops with Duration like Knotting, Gaiting and etc | |

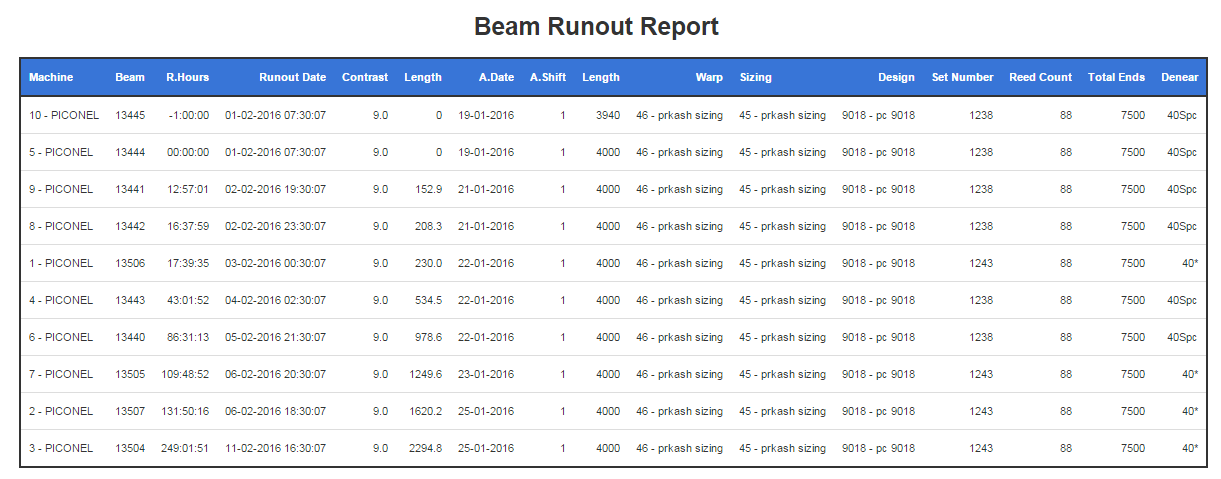

| Design Details | Beam Details |

| Stop Code Details | Operator Details |

| Technician Details | Supervisor Details |

| Operator Group Details | Technician Group Details |

| Supervisor Group Details | |

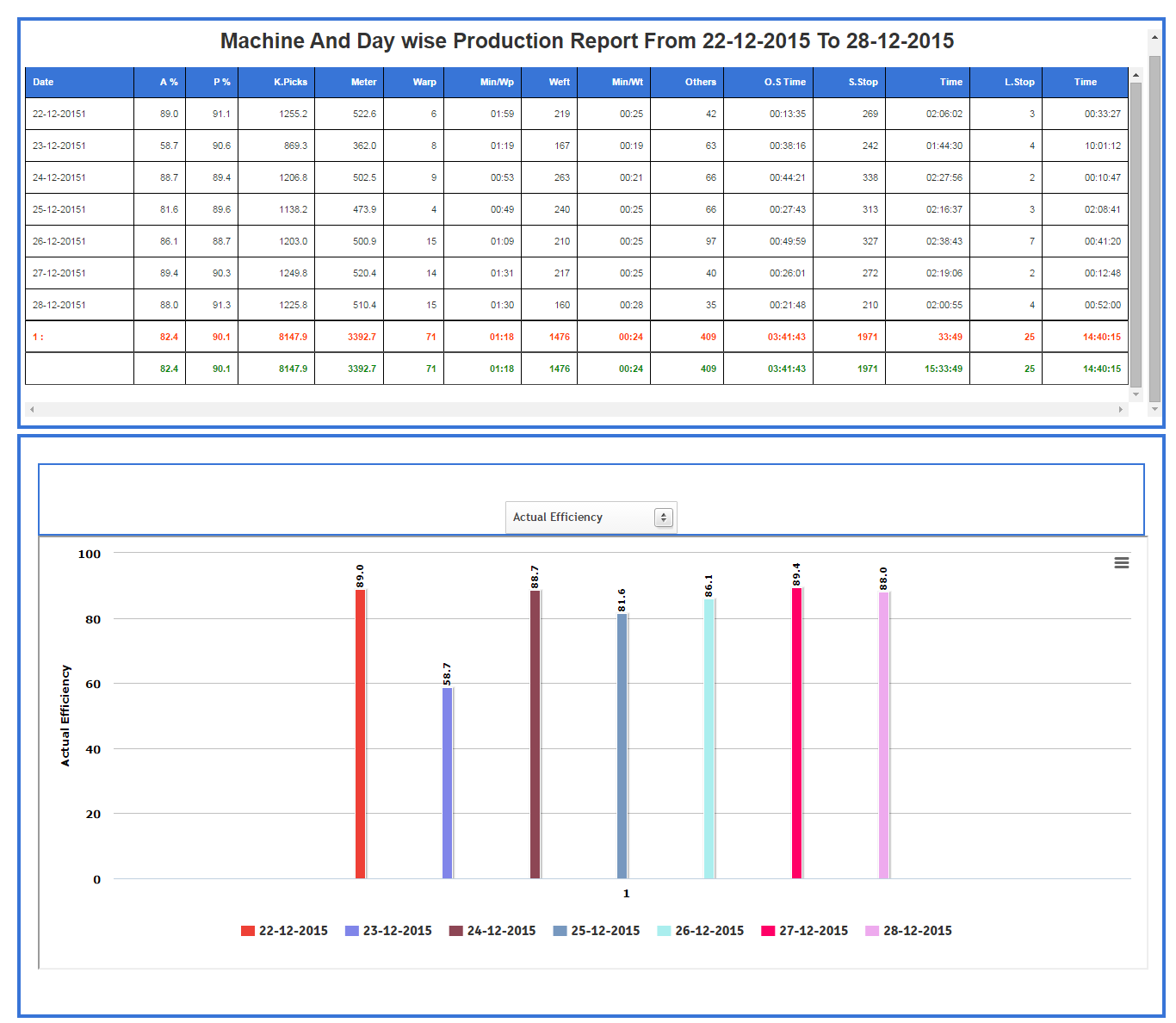

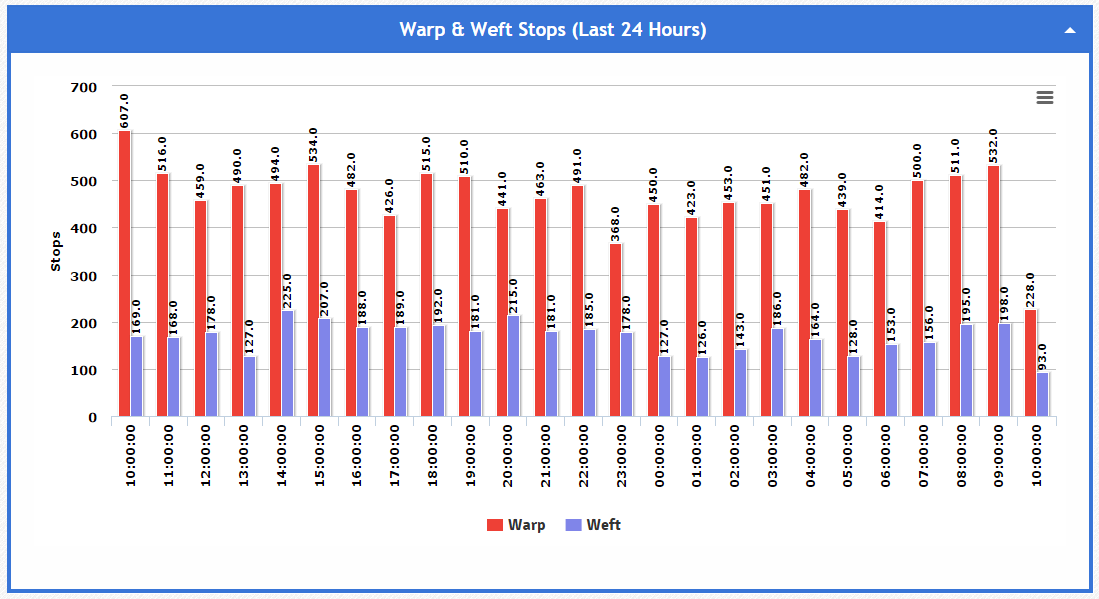

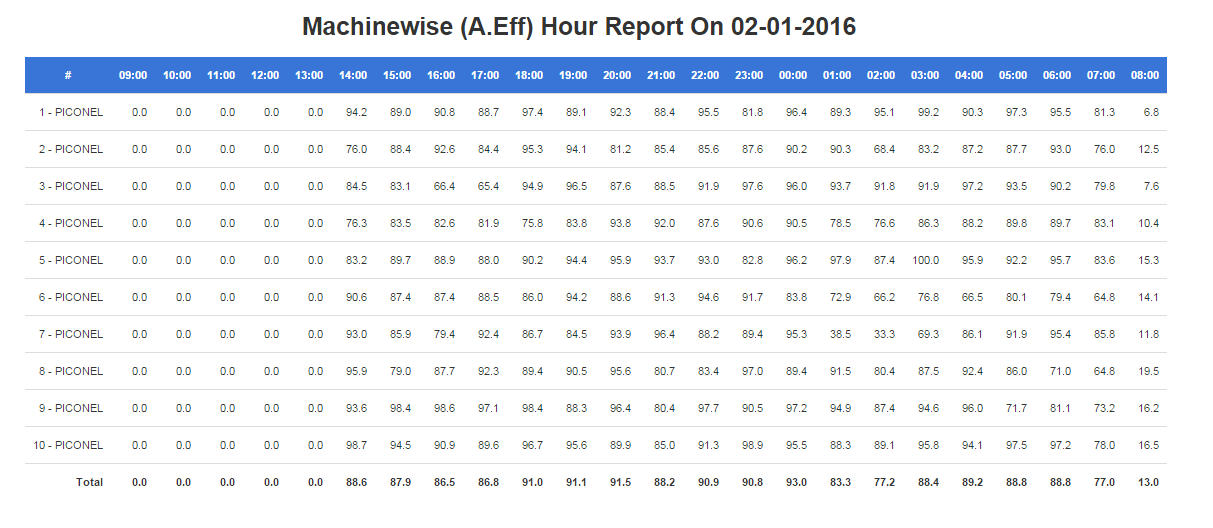

| Hour Wise Production(Kilo Picks and CMPX) and Stop(Warp,Weft and Others) Report with Analysis | |

| Instant alerts for Order Status, Stoppages, Roll-Doff, Beam Runout, etc.. | |

| Production Planning and Order status Reports | Automatic and Manual Roll Doff |

| Roll Doff Alerts & Reports | Beam Planning |

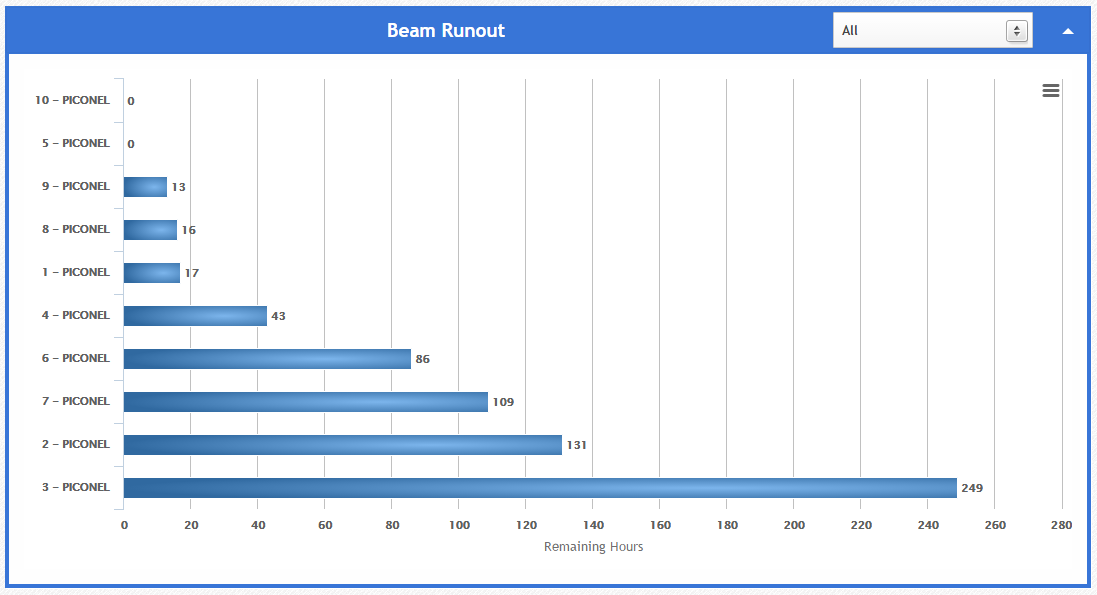

| Beam Analysis | Beam Run out |

| Automatic and Manual Employee Planning and Allocation | Employee Analysis |

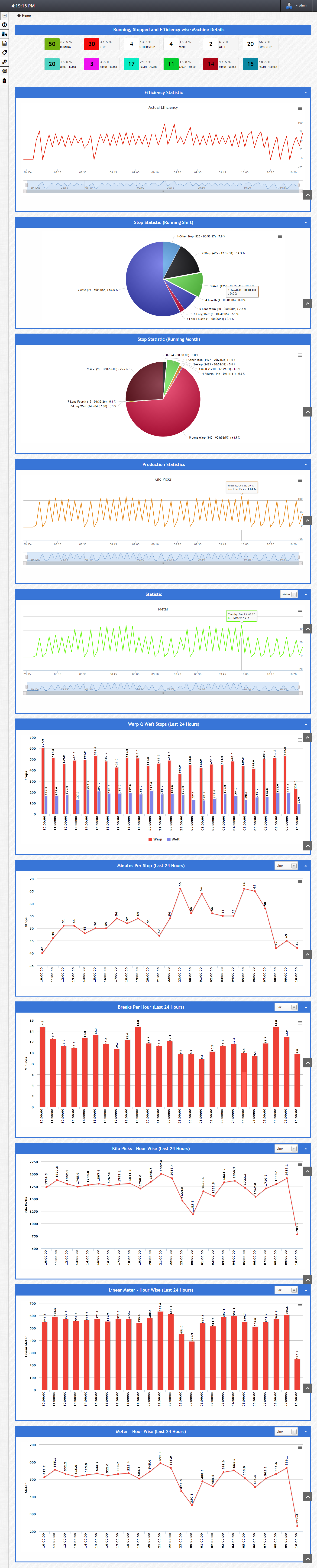

| Dashboard For Immediate Response | Various Types Of Charts Like Line, Bar and Pie |

| Monitoring Screen For Production, Stoppage, RPM and Operator Details | |

| Hour / Shift / Day wise /From To Production and Stoppage Reports | |

| Monthwise Report For Production and Stoppage | |

| Comparision Report For Any TWO Parameters | |

| Units/Kgs | |

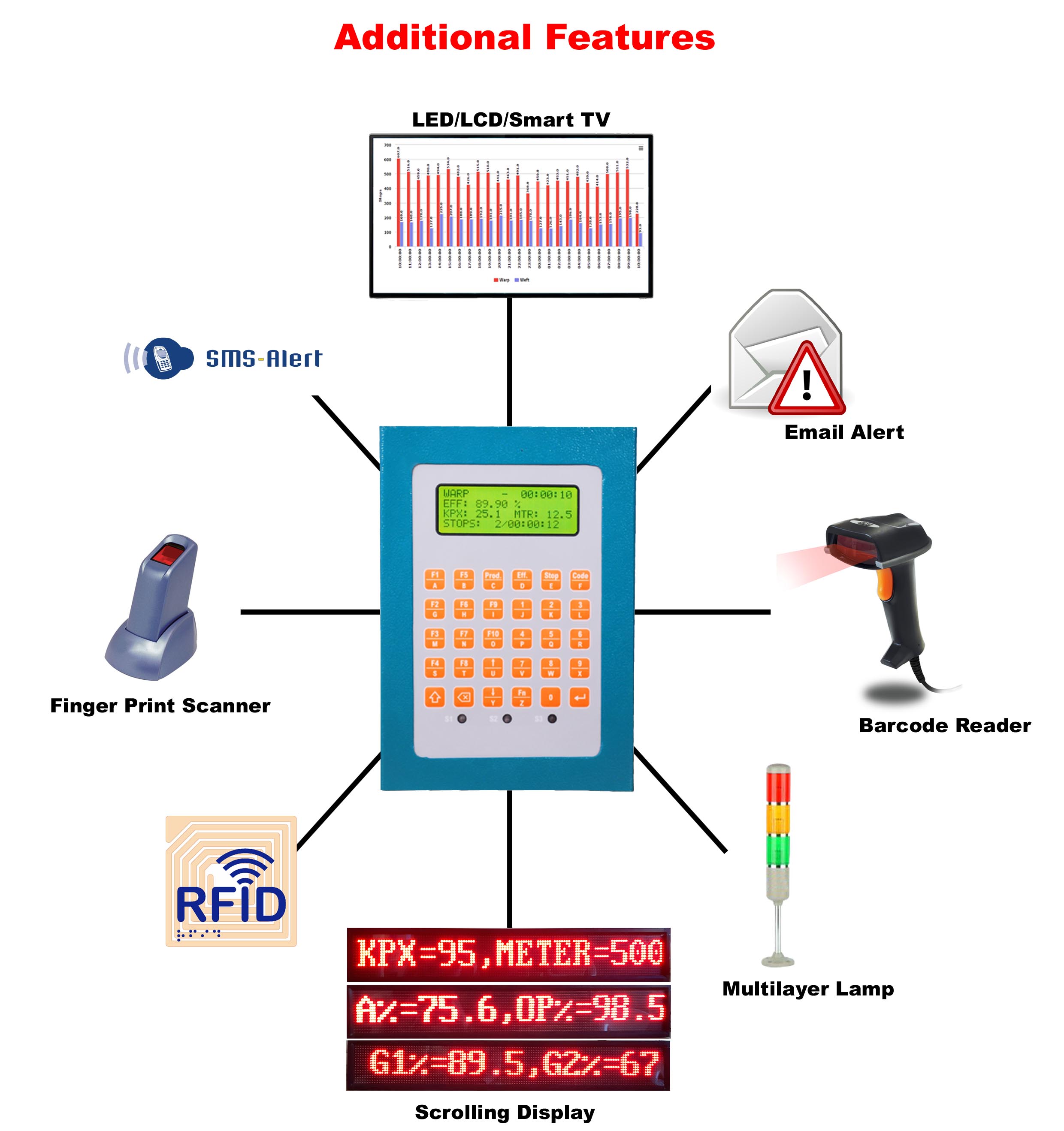

| Usage Of Bar Code | ||

|---|---|---|

| Design Details | Beam Details | Stop Code Details |

| Operator Details | Technician Details | Supervisor Details |

| Operator Group Details | Technician Group Details | Supervisor Group Details |

| Multilayer Lamp | ||

|---|---|---|

| To indicate Warp Stop | Weft Stop | Others Stop |

| Roll-Doff Status | Beam Runout Status | |

| Energy Details | |

|---|---|

| Line Voltage(R Phase,Y Phase, B Phase) | |

| Phase Voltage (RY Phase,YB Phase,BR Phase) | |

| Current (R Phase,Y Phase, B Phase,Total) | |

| Power Factor(R Phase,Y Phase, B Phase, Average - Instantaneous) | |

| Watts (R Phase,Y Phase, B Phase ,Total) | |

| Frequency | |

| VAR (R Phase,Y Phase, B Phase ,Total) | |

| VA (R Phase,Y Phase, B Phase ,Total) | |

| KWH | |

| Air Flow Details | ||

|---|---|---|

| Running CFM | Stopped CFM | Consumed CFM |

| Water Flow Details | ||

|---|---|---|

| Running LPM | Stopped LPM | Consumed LPM |

| Humidity | ||

|---|---|---|

| Minimum Humidity Value(Rh) | Maximum Humidity Value(Rh) | Live Humidity Value(Rh) |

| Temperature | ||

|---|---|---|

| Minimum Temperature Value(Celsius) | Maximum Temperature Value(Celsius) | Live Temperature Value(Celsius) |